I-Surface Mount Technology (SMT) iphambili kwindibano yale mihla yombane. Ukukwazi ukubeka amacandelo ngokukhawuleza nangokuchanekileyo kwiibhodi zesekethe kubalulekile kushishino lwanamhlanje olukhawulezayo lwe-elektroniki. Embindini wobu buchwepheshe kukho amacandelo ahlukeneyo, ngalinye lisebenzela injongo yalo eyahlukileyo. Makhe sihlolisise ngokweendidi kunye neendima zezi zinto zibalulekileyo.

1. Intshukumo kunye nokuchaneka: Ukuqinisekisa ukuchaneka kwinqanaba ngalinye leNdlela

Injini yomatshini we-SMT ibonelela ngomatshini wokuqhuba ofunekayo kwintshukumo echanekileyo. Nokuba kukumisa okukhawulezileyo kwentloko yokubeka okanye ukutyibilika okugudileyo kwee-feeders, i-motor iqinisekisa isantya kunye nokuchaneka kungqamaniso.

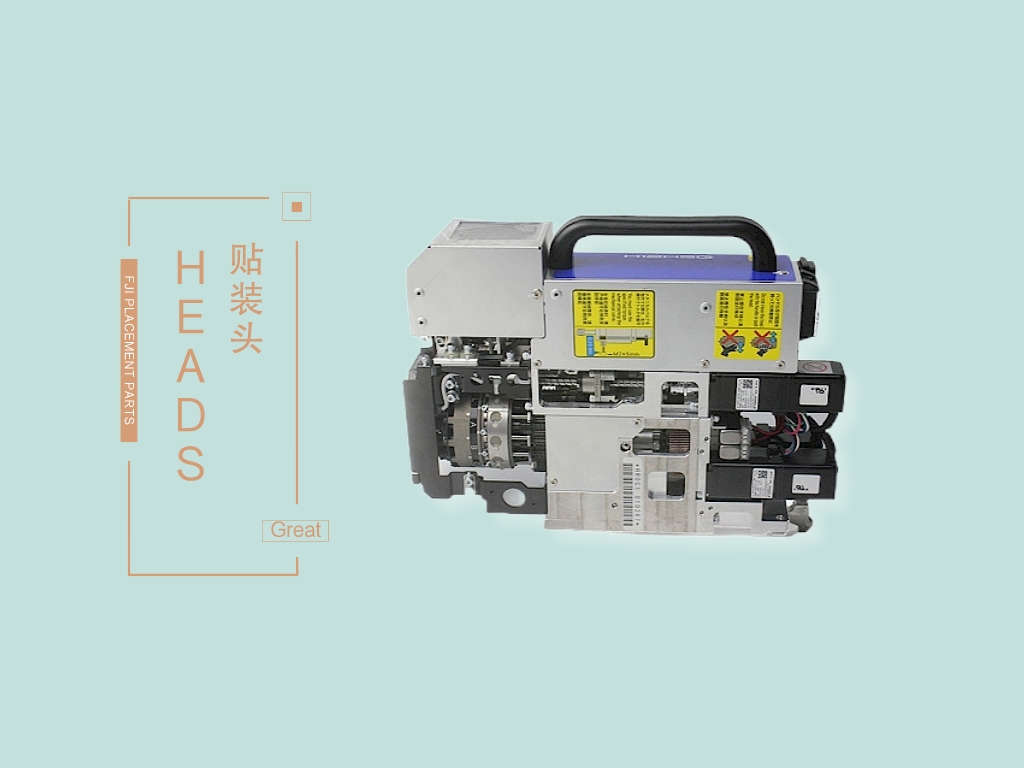

Eli candelo linoxanduva lokuchola amacandelo e-elektroniki kwaye abekwe ngokuchanekileyo kwiPCB. Ifuna ukuchaneka, kwaye ukusebenza kwayo okugudileyo kubaluleke kakhulu kwindibano engenasiphako.

Esi sixhobo siguqulela isindululo esijikelezayo ukuya kwisindululo somgca kunye nokukhuhlana okuncinci, ukuvumela ulawulo oluchanekileyo kunye nokunyakaza, ngakumbi kwimisebenzi yokubeka.

Kanye njengokuba ibhanti liqhuba ipuli, ibhanti ye-SMT ibalulekile ekugcineni ungqamaniso lwamacandelo ahlukeneyo ashukumayo, ukuqinisekisa ukuhamba kakuhle komsebenzi.

2. Ulawulo lweCandelo: Ukunikezela ngokuZinzo kunye nokusebenza kakuhle

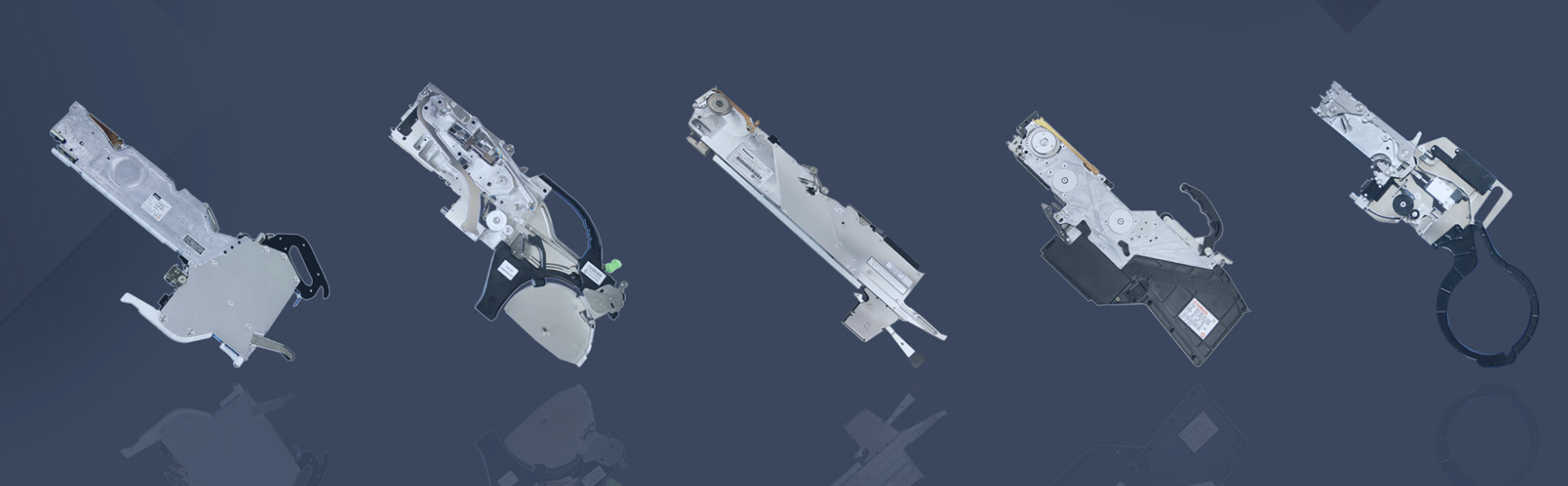

I-SMT feeder idlala indima ebalulekileyo ngokuqinisekisa ukuba amacandelo anikezelwa ngokuqhubekayo kwintloko yokubeka. Kufana nebhanti lokuhambisa lehlabathi le-SMT, linikezela ngecandelo ngalinye kanye ngexesha lokubekwa.

3. UQhagamshelwano kunye nomyalelo: Iintshatsheli zoNxibelelwano

Ukwenza njengetoliki, umqhubi we-servo uqinisekisa unxibelelwano olungenamthungo phakathi kwesoftware kunye namacandelo omatshini, ukuguqulela imiyalelo kwizenzo.

Iziko lemithambo-luvo yokusebenza, ezi bhodi zicwangcisa imiqondiso kwaye zongamela intsebenziswano ehambelanayo yawo onke amalungu omatshini.

4.Ukugcina ubunyulu kunye nokuQuquzelela okuPhuculayo: Undoqo wokungabinasiphako

Ukusebenza kwindawo ecocekileyo kubalulekile. Isihluzi se-SMT siqinisekisa ukuba naziphi na izinto ezingcolisayo ziyasuswa, zithintele iziphene ezinokwenzeka kunye nokuqinisekisa ubude obude bomatshini kunye nemveliso yokugqibela.

Isebenza ngokulawula ukuhamba, le valve iqinisekisa ukuba i-vacuum efanelekileyo yenziwe, eyimfuneko ekuthatheni amacandelo okanye ukuqinisekisa isitywina somoya ngexesha leenkqubo ezithile.

5. Ukufunyanwa kunye neNgxelo: Iimvakalelo zoomatshini be-SMT

Izinzwa koomatshini be-SMT zibhaqa iiparamitha ezahlukeneyo njengobukho becandelo, ukuchaneka kwendawo, kunye nokunye. Banikezela ngengxelo yexesha lokwenyani, beqinisekisa ukuba naziphi na iziphazamiso zichongiwe kwaye zisonjululwe ngokukhawuleza.

Le yimizila yobomi ephethe imiqondiso phakathi kweendawo ezahlukeneyo zomatshini. Ukusuka kwiinjini zokunika amandla ukuhambisa idatha phakathi kweebhodi kunye ne-sensor, iintambo ngabathwali abathe cwaka bolwazi oluyimfuneko.

Kwilizwe elintsonkothileyo lendibano ye-SMT, kuyabonakala ukuba iqhekeza ngalinye, ukusuka kwiBhola Screw ukuya kwiKhamera ye-SMT, libalulekile ekusebenzeni ngokupheleleyo. Xa ufuna ukuphumelela kwemveliso ephezulu, ukuqonda nokugcina la macandelo kubaluleke kakhulu. Soloko ubeka phambili umgangatho, ngakumbi xa ukhangela iindawo, ukuqinisekisa ukuba umatshini wakho we-SMT usebenza ngeyona ndlela ingcono.

www.rhsmt.com

info@rhsmt.com

Ixesha lokuposa: Oct-27-2023